Our deep engineering expertise and commitment to developing novel solutions empower biotech companies to create new consumables and instruments. We combine rapid, iterative prototyping with proven development methods to transform complex ideas into dependable, production-ready solutions. Our process consistently drives practical advancements that support meaningful progress in the life sciences.

We design and build advanced lab and process equipment to support scientific research and industrial production.

We create custom instruments that accelerate research and development in sequencing and assay systems.

We design and manufacture the specialized microfluidic chips and the integrated control systems needed for precise fluid manipulation.

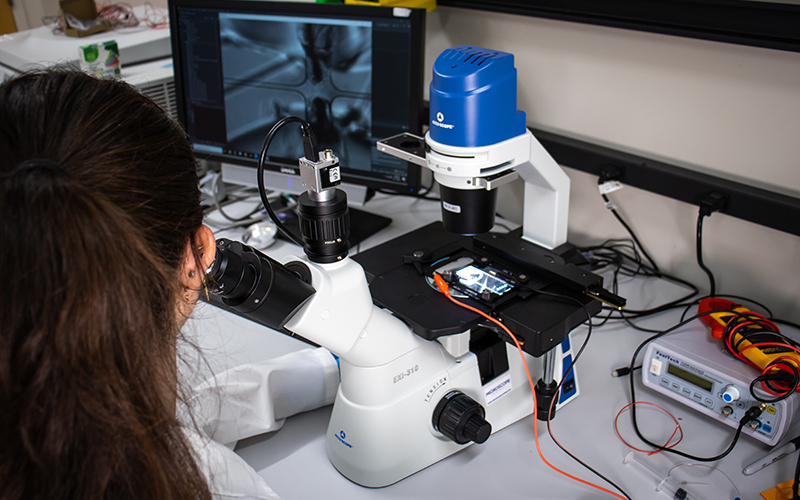

We design and build unique microscopes for advanced imaging and research, programming them to monitor cell health and assess cell confluency.

We develop custom incubators to meet specific environmental control requirements for biological samples, with additional capabilities including custom imaging, fluid management, and more.

We create innovative fluidic platforms for simulating human organs to advance research and drug development.

Life Sciences Expertise

When you need to prove a concept, you need the right tools to get there quickly. Our facility has an expansive set of tools for rapid prototyping, including a diffusion bonder, solvent bonding, UV gluing, an ultrasonic welder, and a laser welder. We also maintain a stock of commonly used materials, such as Cyclic Olefin Copolymer (COC) and Pressure-Sensitive Adhesive (PSA), to enable fast iteration. This allows us to quickly test different technologies for your consumable and look ahead to production during the prototyping phase.

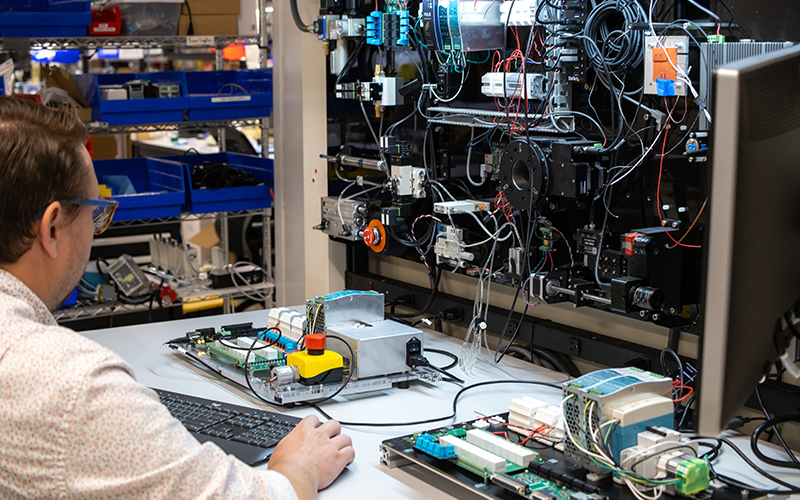

We have a collection of electromechanical components and a proprietary software stack ready to go in our lab. This allows us to rapidly build a proof of concept for your instrument and get you an answer in days, not weeks. We have experience with a wide range of applications, leveraging our expertise in DNA electrophoresis, point-of-care diagnostics, microfluidics, organ-on-a-chip, custom microscopes, and custom incubators.

We employ advanced techniques, including high-speed, high-resolution, high-magnification, and fluorescent imaging, to capture critical fluidic behaviors and accelerate prototyping for life science innovations. This sophisticated imaging, combined with our custom-designed automated test systems, allows us to simulate real-world conditions and collect detailed performance data throughout extensive testing cycles. Our approach accelerates iteration, optimizes functionality, and provides the confidence needed to advance your life science instruments and consumables from concept to market-ready solutions.

We’ve invested in our facilities to support your project from concept to production. We have a certified BSL-2A Biosafety Lab and ISO Class 7 Clean Rooms. Re:Build Fikst has implemented an electronic Quality Management System (eQMS) across its production operations and is currently pursuing ISO 13485 certification. This ensures that your project meets the highest standards for safety and quality from the very beginning.

Fill out the form below and someone from our team will be in touch with you shortly.